Dust Collectors

Online Pulsejet Bag Filters Using Nonwoven Needle Felt Filter Media :

AIR TECHNIKO series bag filters are capable of handling in excess of 600 gm/Nm3 dust loads with guaranteed emission level of even less than 10 mg/Nm3, these bag filters are capable of handling dust having majority of particulate size > 10 µm. With membrane laminated filters, they can handle very fine dust particulates.

• Modular construction, up to 1000 m2 filter area in a single module, capacity range in excess of 200,000 m3/h with multiple modules.

• Temperature rating up to 350 deg C.

• Available in filter lengths from 3000 mm to 5000 mm.

• Uses injector nozzle pulsing for most efficient online cleaning of filters, eliminates energy sapping conventional venturi and requires minimum pulsing at large intervals saving on compressed air energy.

• MS bag holding plates and easy to install snap band filters ensure zero leakage, critical to emission control.

• Long lasting, light weight, spirally stiffened galvanized bag cages minimize deformations while handling & transport.

• Large & high capacity rotary airlocks with adjustable vane tips for dust discharge designed to operate under (-) 800 mmwc.

• High capacity screw conveyors for larger modules, designed to operate without hanger bearings for maintenance free operation.

• Available with wide filter media selection of Polyester / Polypropylene / Acrylic / m- PTFE media with surface treatments of oil/water repellant, anti-static, spark resistant, flame retardant etc to suit various applications.

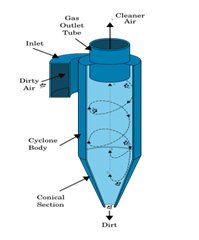

Multicyclone Separator :

Multi Cyclone type dust collectors are used as an Air Pollution Control Device intended for separation of suspended particulate matter from gas/air stream. It is mostly used for arresting efficiently particles having size larger than 10 micron. The separation is based on generation of centrifugal force and coarse particles falling at a gas stream due to inertia action.

• CI cyclone of approx 150 to 250 mm ID with CI gas inlet guide vanes.

• MS casing for housing the cells which are suspended from MS tube sheet.

• Clean air leaves through exhaust pipe and collected in a plenum chamber at top.

• Dust separated is collected in hopper underneath and discharged through rotary air lock .